Custom parts manufacturers

Whether it’s simple parts or complex structures, AFI Industrial Co., Ltd. can offer you fast, flexible and precise customized solutions.

Tailored for you

One-stop Solution, Reducing Your Procurement Process

30+ kinds of technical support and more than 10+ surface treatments are enough to meet your product needs

Quality Control

We have a perfect quality control system that guides employees to strictly control product quality at every production link,Ensure that the customer’s metal parts meet the drawings and assembly requirements.

Cost Control

We have a variety of machining and surface treatment equipment. During the processing of parts, we can eliminate the intermediate costs of outsourcing, ensuring that every penny you spend is clear and transparent.

Delivery Schedule Control

After receiving the inquiry, our team can respond within 2 hours and provide a quote within 4 hours. Moreover, we can deliver the goods within 3 to 15 days depending on the quantity,ensure your delivery schedule requirements.

100+ Reviews

Our custom services bring your ideas to life

With over 20 years of machining experience and a professional design and sales team, we support any drawing or file format to meet custom requirements. Using CNC milling, laser cutting, five-axis machining, and other processes, we can manufacture custom parts with special shapes, multiple curved surfaces, or high precision (±0.01mm). Our one-step molding technology reduces processing steps, shortens lead times, and helps customers save over 30% in production costs.

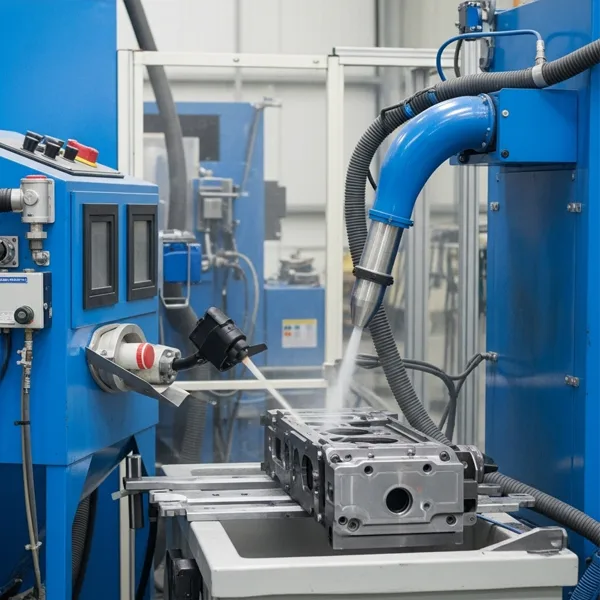

CNC Machining Service

We use advanced CNC processing technology to reduce processes and quickly customize high-precision, complex parts for customers, helping you improve efficiency, reduce costs, and enhance market competitiveness.

Learn More

Casting Service

We offer aluminum alloy/zinc alloy die-casting services. Utilizing advanced molds and techniques, we can mass-produce thin-walled and complex structural components with precise dimensions and smooth surfaces.

Learn More

Heat Treatment Service

We provide professional quenching, tempering and other heat treatment services, equipped with advanced equipment to ensure that our products meet the hardness, toughness and wear resistance required by customers.

Learn More

Surface Treatment Service

We provide surface treatments such as anodizing, electroplating, spraying, and passivation to help you improve the corrosion resistance, wear resistance, and appearance of your products to meet diverse application needs.

Learn MoreOur quality control process

100% full inspection system ensures that every part is delivered with zero defects

Our advanced testing equipment and professional quality management team ensure you receive stable and reliable product quality. This enables you to make purchases with peace of mind and have confidence in your cooperation.

①

Incoming material inspection

For the incoming inspection of raw materials, we employ techniques such as spectroscopy analysis and three-coordinate measurement to comprehensively test the chemical composition, dimensional accuracy, and mechanical properties of the materials, ensuring that they meet the requirements stipulated in the drawings and technical specifications.

②

Process inspection

We employ SPC (Statistical Process Control) to monitor the fluctuations of key product parameters in real time. We promptly identify and correct deviations to ensure the consistency of the products for our customers.

③

Final product inspection

In the final product quality control stage, we conduct 100% comprehensive inspections on the product’s appearance, dimensional accuracy, and functional performance using precision detection equipment such as three-coordinate measuring instruments and spectrometers, ensuring that the product meets the requirements for use, assembly, and display by customers.

④

Shipping inspection

We implement a final inspection process before shipment. We 100% verify the consistency between the shipping documents and the actual goods to ensure that the product packaging is intact and the protective measures meet the standards. We then send the defect-free products to the customers.

Our Manufacturing Partner

Received unanimous recognition from customers in over 30 countries and regions around the world!

“As a startup, our first order only required 50 precision fixtures. AFI not only accepted small batches, but also optimized our design for free, reducing processing costs by 42%. Now, after the B round of financing, we have outsourced all CNC to them..”

Emma W. | CEO

NanoGrip Tech

“The harmonic gears of the precision reducer require 50 CNC processes. Engineers from AFI Industrial Co., Ltd. came to Osaka to exchange ideas with us, presenting an improvement plan: by customizing the tooling fixtures, the number of clamping operations was reduced by 4 times, and the vibration and noise were decreased by 15 dB. Our president said, “This is the strength of Chinese manufacturing.”

田中拓也

新藤ロボティクス

“Would you like to entrust the CNC machining of the 0.8mm diameter escapement wheel shaft to a Chinese factory? At first, the entire board opposed it. But AFI Industrial Co., Ltd. achieved a surface roughness of Ra0.05μm using mirror turning technology, which is two levels higher than the standard of our Swiss supplier! Even more astonishing is that the composite processing enables 14 processes to be completed in one setup, and the annual production capacity has been increased to 300,000 pieces. The future of precision watchmaking lies in China.”

Elena Müller

Montres de Genève

“The processing of Inconel 718 turbine cover for jet engines has deterred European suppliers – until they met AFI Industrial Co., Ltd.! Their ultra-high pressure cooling cutting technology has increased the tool life by 8 times, and all 38 complex curved parts passed the AS9100D three-coordinate inspection. The air freight cost is 120,000 euros lower per batch than local procurement. Chinese CNC is rewriting the rules of the aviation supply chain.”

Luc Bernard

AeroPower Dynamics

“The yaw gear ring of the 7.2MW wind turbine has a diameter of 2.4 meters. In the past, it was cast in 12 sections and then pieced together. The gantry five-axis machining center of AFI Industrial Co., Ltd. has for the first time achieved overall processing! Their unique gravity compensation algorithm reduces cutting vibration by 40%, and the tooth shape accuracy reaches DIN 3 level. The weight of a single piece is reduced by 800 kg, and the installation time at the tower top is shortened by 6 weeks – this is no longer just part processing, but a revolution in wind energy engineering!”

Emma Johnson

TerraPower Renewables

“The flatness requirement for the base of the external lens is 0.5 μm. AFI Industrial Co., Ltd. has achieved this with a liquid nitrogen cooling process, reaching 0.3 μm, and the unit price is 60% lower than that of the Swiss supplier. This has completely changed our perception of ‘Made in China’.”

Prof. Zhang

OptiSpectra

Let us work together to create brilliance

AFI Industrial Co., Ltd.provides professional machining solutions, including product design, engineering drafting, CNC programming, precision manufacturing, laser cutting, surface treatment, assembly, and packaging. Our production process system can help customers shorten production cycles by 50%, reduce operating costs by 30%, and enhance market competitiveness.

Latest Blogs

The latest and most exciting posts and articles on machining