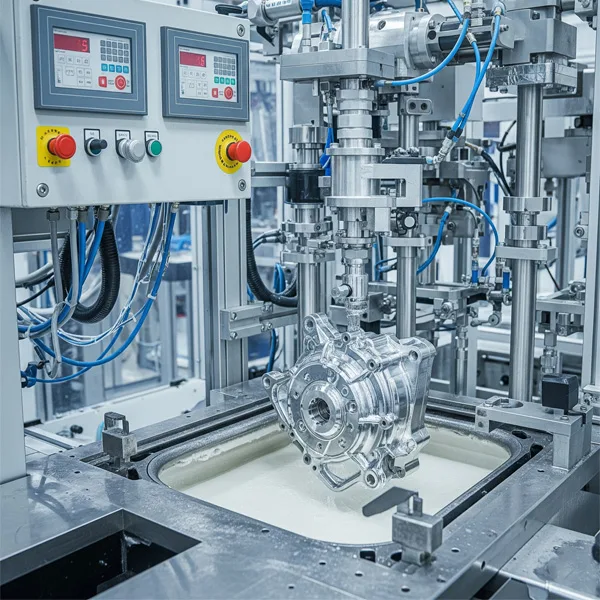

Surface Treatment

AFI Industrial Co., Ltd. offers customers a one-stop surface treatment solution. Based on the material, function and aesthetic requirements of the customers, we can precisely match a complete set of processes including anodizing, electroplating, painting, powder coating, sandblasting, polishing, etc., to create high-value and sustainable surface treatment effects for you.

From 0.1 mm precision parts to 3 m large structural components, it covers the entire range, featuring the widest processing range in the industry.

72-hour prototyping, 7-day batch production, 24-hour after-sales response. This is 30% faster than the industry average. For urgent orders, there is no price increase.

Years in Business

5-Star Reviews

Active Customers

Counties Served

Our Surface Treatment Capabilities

AFI Industrial Co., Ltd. has over 20 fully automated lines and more than 30 environmentally friendly processes. Processes such as anodizing, electroplating, painting, powder spraying, wire drawing, sandblasting, and polishing can be switched at any time. For products with a minimum hole diameter of 0.1 mm and a maximum workpiece length of 3 meters, we can quickly produce samples within one day and achieve mass production within three days.

You can freely choose the color and texture. Salt spray, wear resistance, and scratch resistance tests can all be completed in the factory in one go, making your products both attractive and durable, meeting your quality requirements.

Custom Surface Treatment Materials

We specialize in various surface treatments for metal materials. All metal substrates, including aluminum, magnesium, titanium, steel, copper, zinc, and other high-temperature alloys, can be processed in one step. From anodizing to electroplating, spraying, polishing, and more, whether you need anti-corrosion, wear resistance, conductivity, heat insulation, or decorative effects, we can deliver precise and maturely processed products to you on a large-scale production basis.

Aluminum materials can be upgraded in terms of functionality or appearance through almost all mainstream metal surface processing techniques. Our company has a mature and large-scale surface treatment solution for aluminum materials, including processes such as anodizing, electroplating, spraying, sandblasting, wire drawing, and polishing, which can meet various surface treatment requirements of customers for aluminum materials.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Magnesium materials have extremely high reactivity. Our company can provide customers with a complete set of processes including micro-arc oxidation to form ceramic-grade MgO films, electroless nickel/copper plating for conductivity and corrosion resistance, chrome-free passivation combined with powder coating to resist salt fog, PVD coating of Al/TiN to enhance wear resistance, as well as conductive paint and anodized coloring. These processes fully meet the strict requirements of the military industry, 3C products, and automotive lightweighting for high-strength corrosion resistance, electromagnetic shielding, and appearance decoration.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Our company can complete a full range of processes for titanium materials, including anodizing coloring, electroplating, sandblasting + polishing + mirror polishing finishing, to meet the multiple demands of aerospace, medical implants, and consumer electronics for lightweight, high strength, corrosion resistance, decoration, and biocompatibility.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Steel is strong and durable, has high tensile strength, is resistant to corrosion, heat and fire, and is easy to shape. It has a wide range of applications, from building materials and structural components to automotive and aerospace components. Whether it is stamping, casting, or CNC cutting, we can ensure that the excellent processing properties of steel are fully utilized to meet your technical requirements.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Our company can complete all the electroplating processes such as nickel plating, silver plating, gold plating, tin plating, and chrome plating for copper materials, as well as finishing processes like sandblasting, mirror polishing, and wire drawing. These comprehensive services fully meet the diverse demands of the power, electronics, 5G communication, bathroom, and handicraft industries for high conductivity, strong corrosion resistance, resistance to high-temperature oxidation, and high-end appearance.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Our company is capable of performing processes such as powder coating, mechanical polishing and wire drawing finish on zinc materials. This enables us to fully meet the demanding requirements of automotive fasteners, building hardware, and electronic enclosures for superior corrosion resistance, weather resistance, conductivity, and high-end appearance.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

In addition to metals, we also offer one-stop surface treatment services for “other materials” such as plastics, ceramics, glass, carbon fibers, and wood, fully meeting the diverse demands of the 3C, automotive, construction, home furnishing, and medical industries for lightweight, weather-resistant, conductive, heat-insulating, and high-end appearance

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Why Choose Our Surface Treatment Service?

AFI Industrial Co., Ltd. is capable of providing various surface treatment services for stainless steel, aluminum alloy, titanium alloy and various castings in the same industrial park. It can quickly meet the surface quality requirements of customers for the materials.

One-to-one communication service

You only need to upload any type of drawings and you will receive a quote within 2 hours. Our professional engineers will analyze your design to prevent misunderstandings and communicate with you to provide you with a reasonable quote.

High-quality surface treatment

Our surface treatment service adopts imported production lines and CNAS laboratories. The thickness of the film layer, color difference, and salt spray data can be controlled in real time, and the yield rate is ≥ 99.2%.

Fast delivery cycle

Our surface treatment service can provide 72-hour sample production, 7-day batch delivery, and 24-hour after-sales response. It is 30% faster than the industry average, reducing your waiting time and helping you seize the market opportunity..

Real-time messaging

To protect your rights, we will provide each customer with exclusive technical support throughout the entire process from quotation to delivery, so you can contact us at any time. We will respond and answer any questions you raise quickly until you receive the parts you are satisfied with.

Surface Treatment FAQS

After anodizing, the size of the product will change. The change is uniform. As long as there is sufficient allowance reserved in advance, the size can be fully controlled and will not exceed the tolerance limit.

Our production processes include anodizing, electroplate, spray painting, powder coating,brushed, sandblasting and polishing. Our engineers will select the most suitable surface treatment method for you based on your performance requirements.

For the products that have undergone anodizing treatment, our company must conduct tests on the film thickness, appearance and color difference, as well as performance evaluation. Including adhesion, hardness, wear resistance, corrosion resistance, sealing quality, surface roughness, porosity, dimensional change, etc.

Brushed will slightly reduce the corrosion resistance, but this can be “recovered” through subsequent passivation, coating or sealing processes; it has little negative impact on hardness and wear resistance, and instead, due to surface hardening, it can be slightly improved.

Let us work together to create brilliance

AFI Industrial Co., Ltd.provides professional machining solutions, including product design, engineering drafting, CNC programming, precision manufacturing, laser cutting, surface treatment, assembly, and packaging. Our production process system can help customers shorten production cycles by 50%, reduce operating costs by 30%, and enhance market competitiveness.