Heat Treatment

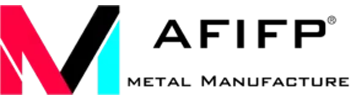

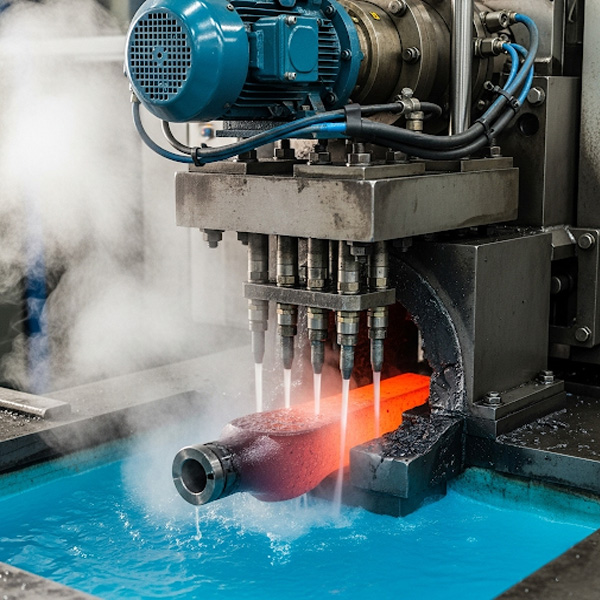

AFI Industrial Co., Ltd.provide comprehensive heat treatment services to help customers accurately improve the hardness, wear resistance and fatigue resistance of metals. We use advanced equipment such as vacuum heat treatment and controlled atmosphere furnace to ensure temperature uniformity (±5℃) and process stability.

Supports difficult-to-process materials such as titanium alloy/high-temperature alloy, and one-time forming of complex parts.

Tolerance down to 0.01mm

The fastest delivery time is 3-15 days

Years in Business

5-Star Reviews

Active Customers

Counties Served

Our Heat Treatment Capabilities

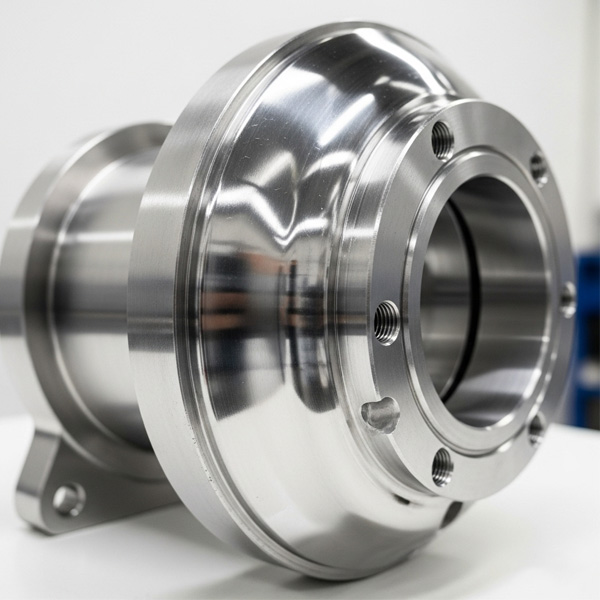

AFI Industrial Co., Ltd. is a professional manufacturer of parts. We can provide heat treatment solutions for your metal parts. Whether it’s simple structural components or complex precision parts, we can precisely enhance the hardness, wear resistance, and fatigue resistance of materials such as stainless steel, alloy steel, and titanium alloy, ensuring zero oxidation, zero decarburization, and strictly controlling the deformation within ≤ 0.05mm/m, meeting the heat treatment requirements of our customers.

Custom Heat Treatment Materials

We have a complete and advanced heat treatment production line, which can provide full-service for quenching and tempering of materials such as aluminum alloys, steel, stainless steel and titanium alloys. We ensure that the performance, size and data of each batch of parts can be controlled. The delivery time can be as fast as 24 hours. Whether it is a small batch or a large batch, the quality is equally precise and reliable.

Steel is strong and durable, has high tensile strength, is resistant to corrosion, heat and fire, and is easy to shape. It has a wide range of applications, from building materials and structural components to automotive and aerospace components. Whether it is stamping, casting, or CNC cutting, we can ensure that the excellent processing properties of steel are fully utilized to meet your technical requirements.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

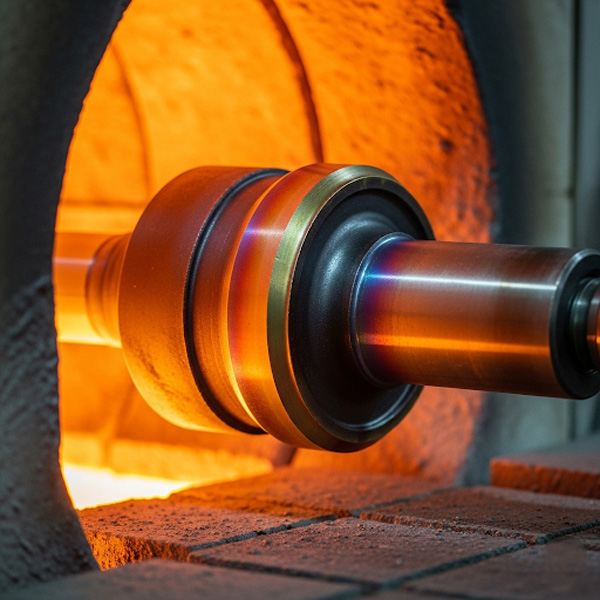

Titanium is an advanced material with excellent corrosion resistance, biocompatibility and strength-to-weight ratio. These unique properties make it the material of choice for many engineering challenges in the medical, energy, chemical processing and aerospace industries.。

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Stainless steel alloys have high strength (up to 2000MPa), ductility (elongation ≥40%), wear resistance and corrosion resistance (passed 1000 hours salt spray test). We use advanced CNC processing and laser welding technology to ensure that stainless steel parts play its best performance in applications such as medical equipment, food machinery, chemical equipment, etc.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Aluminum alloy has the characteristics of low density, high specific strength, corrosion resistance and easy formability. Through heat treatment, its strength can be doubled and its service life can be increased by a hundred times. It is widely used in various scenarios where weight reduction is required without sacrificing performance, such as aerospace, automotive new energy, mold and tooling, etc.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Why Choose Our Heat Treatment Services?

One-to-one communication service

You only need to upload any type of drawings and you will receive a quote within 2 hours. Our professional engineers will analyze your design to prevent misunderstandings and communicate with you to provide you with a reasonable quote.

Precision heat treatment

We control the four variables – temperature, atmosphere, time and deformation – within an extremely narrow range through a “programmable, monitorable and traceable closed-loop system”. Before delivery, conduct a detailed inspection of the product to ensure its stable quality and traceability.

Fast delivery cycle

We have advanced heating and cooling equipment, which cover 95% of industrial heat treatment scenarios. These devices can ensure a rapid delivery cycle of 3 to 15 days. We also arrange the order sequence reasonably to meet the demand.

Real-time messaging

To protect your rights, we will provide each customer with exclusive technical support throughout the entire process from quotation to delivery, so you can contact us at any time. We will respond and answer any questions you raise quickly until you receive the parts you are satisfied with.

Heat Treatment FAQS

Heat treatment refers to a metal processing technique in which materials are heated, held at a certain temperature, and then cooled, in order to achieve the desired microstructure and properties. It is a thermal processing method carried out in the solid state.

When metals are heated to a specific temperature range, they can become purer and harder. Heat treatment usually results in stronger metals. However, some treatments may also make the metals weaker.

During the heat treatment process of metals, the temperature gradually rises and their volume expands. The degree of expansion varies for different metals.

Heat treatment includes four types: quenching, tempering, annealing and normalizing. It can be improved according to the customer’s requirements to achieve the expected results.

Let us work together to create brilliance

AFI Industrial Co., Ltd.provides professional machining solutions, including product design, engineering drafting, CNC programming, precision manufacturing, laser cutting, surface treatment, assembly, and packaging. Our production process system can help customers shorten production cycles by 50%, reduce operating costs by 30%, and enhance market competitiveness.