CNC Machining Services

AFI Industrial Co., Ltd. provide a variety of CNC processing solutions, including CNC turning, CNC milling, cutting, welding and other core processes, supporting from prototype development and production to on-demand part generation, whether simple or complex part structure, can meet your design needs.

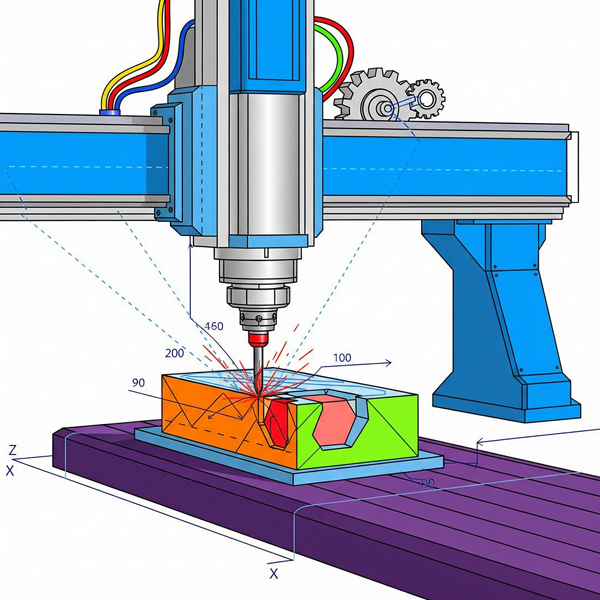

3/4/3+2/5 Axis CNC machining

Tolerance down to 0.001mm

The fastest delivery time is 3-15 days

Years in Business

5-Star Reviews

Active Customers

Counties Served

Our CNC Machining Capabilities

If you are looking for a reliable precision parts manufacturer to customize metal parts, AFI Industrial Co., Ltd. has a wide range of CNC turning and milling centers that will be your first choice. Whether the geometry is simple or complex, we have strong CNC machining capabilities that can meet customers’ strict tolerances and high precision requirements.

Custom CNC Machining Materials

We have a complete metal material library with more than 100 kinds of high-quality metal materials. We help customers quickly develop prototypes and manufacture high-precision complex parts. These materials can meet diverse needs and provide solid material guarantees for customers’ production and manufacturing work at different stages and with different requirements.

Aluminum alloys have a good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.It is suitable for many fields such as aerospace, automobile manufacturing, electronic equipment, etc.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Brass has high mechanical strength and low friction properties, making it an ideal material for processing corrosion-resistant mechanical parts. Our CNC machining services are suitable for manufacturing key components in harsh environments such as the marine industry, ensuring that the parts have a longer service life under harsh conditions such as salt spray and humidity.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Bronze is resistant to seawater corrosion and has low mechanical strength. It is suitable for manufacturing various low-stress parts through CNC precision machining.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Steel is strong and durable, has high tensile strength, is resistant to corrosion, heat and fire, and is easy to shape. It has a wide range of applications, from building materials and structural components to automotive and aerospace components. Whether it is stamping, casting, or CNC cutting, we can ensure that the excellent processing properties of steel are fully utilized to meet your technical requirements.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Titanium is an advanced material with excellent corrosion resistance, biocompatibility and strength-to-weight ratio. These unique properties make it the material of choice for many engineering challenges in the medical, energy, chemical processing and aerospace industries.。

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Stainless steel alloys have high strength (up to 2000MPa), ductility (elongation ≥40%), wear resistance and corrosion resistance (passed 1000 hours salt spray test). We use advanced CNC processing and laser welding technology to ensure that stainless steel parts play its best performance in applications such as medical equipment, food machinery, chemical equipment, etc.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Copper’s high corrosion resistance helps prevent rust, and its thermal conductivity is also conducive to CNC processing. It is suitable for the manufacture of parts with strict electrical/thermal conductivity requirements, such as high-precision connectors and heat dissipation modules.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Zinc, as a special functional metal, is brittle at room temperature. After fine polishing, it presents a shiny gray metallic luster (reflectivity can reach 80%). It is unique in decorative and protective applications.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Alloy materials, through the optimization of composition ratios and heat treatment processes, possess high strength, heat resistance, corrosion resistance and other properties. They are applied in high-end manufacturing fields such as aerospace engine components, chemical corrosion-resistant equipment, and key parts of precision machinery, and can meet the usage requirements under harsh working conditions.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Plastics, woods and stones and other materials are widely used in various industries. Our company can also customize and process various parts made of plastics, woods, stones and other materials for our clients.

Commercial Plans

Call our office to speak with our sales team regarding commercial accounts and customized service plans.

+86 139-2924-0170

Dedicated service technician

Priority appointment booking

Discounts on parts and labor

One year commitment required

Why Choose Our CNC Processing Services?

One-to-one communication service

You only need to upload any type of drawings and you will receive a quote within 2 hours. Our professional engineers will analyze your design to prevent misunderstandings and communicate with you to provide you with a reasonable quote.

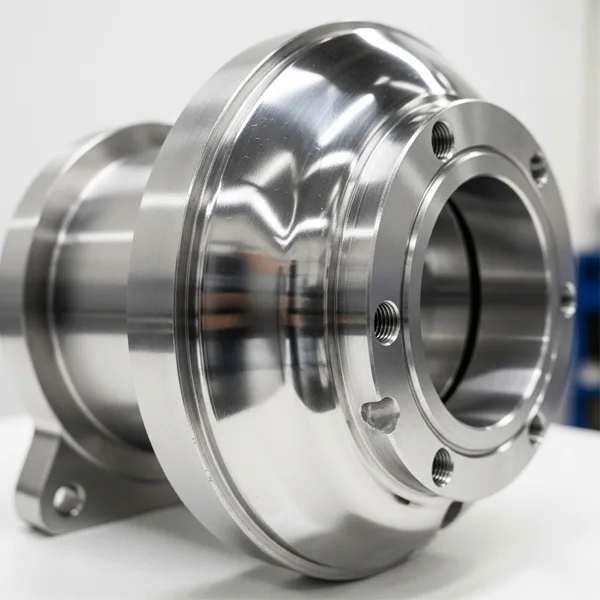

Precision production parts

We take materials, processing, surface treatment and coordinate measuring machine (CMM) testing seriously to ensure the consistent quality of parts from prototype design to mass production. Before delivery, we will conduct a detailed inspection of the quality of the parts to eliminate defective products.

Fast delivery cycle

We have introduced advanced five-axis CNC machining centers and equipped with professional quotation personnel to ensure a fast delivery cycle of 3-15 days. At the same time, we will reasonably set the order priority according to the specific needs of customers and the complexity of the order.

Real-time messaging

To protect your rights, we will provide each customer with exclusive technical support throughout the entire process from quotation to delivery, so you can contact us at any time. We will respond and answer any questions you raise quickly until you receive the parts you are satisfied with.

CNC Machining Tolerance

| Feature | Description |

| General Tolerances | Metals: +/- 0.005“(+/- 0.127 mm) Plastics: +/- 0.010”(+/- 0.254 mm) |

| Precision Machining Tolerances | ±0.0004″ (0.01mm) |

| Min Wall Thickness | 0.5mm |

| Maximum Part Size | CNC Milling: 4000×1500×600 mm CNC Turning: 200×500 mm |

| Minimum Part Size | CNC Milling: 5×5 ×5 mm CNC Turning: 2×2 mm |

| Surface Finish (As Machined) | 125 Ra or better |

| Lead Time | 3-5 Working Days |

CNC Machining FAQS

CNC machining is a wide-ranging manufacturing category involving multiple computer-managed processes. The objective is to remove enough raw material from a piece to achieve a state of near completion

Improving the surface quality of CNC machining is a systematic project. Our company has coordinated optimization in multiple aspects including tools, processes, equipment, environment and post-processing, thereby achieving a dual improvement in quality and efficiency.

The influence of cutting speed on surface quality follows a non-linear and material-sensitive pattern. It requires a comprehensive consideration taking into account the material properties, tool condition, and cooling conditions. Our company can systematically utilize cutting speed to optimize surface quality and avoid hidden defects caused by “blind speed increase”.

The types of machining services provided by our company include turning, milling, sheet metal , metal stamping, pipe bending, gear hobbing, welding, cutting, grinding, etc. We welcome you to visit our company for a tour.

Turning and milling are the two fundamental processes in machining.

Turning involves the rotation of the workpiece and the straight/curved movement of the tool, resulting in a rotating body;

Milling, on the other hand, involves the rotation of the tool and the fixation/movement of the workpiece, generating a plane/ cavity/surface. In general, for round parts, turning is used; for square, curved, or parts with holes, milling is employed. For complex parts, the combined method of turning and milling is selected.

Let us work together to create brilliance

AFI Industrial Co., Ltd.provides professional machining solutions, including product design, engineering drafting, CNC programming, precision manufacturing, laser cutting, surface treatment, assembly, and packaging. Our production process system can help customers shorten production cycles by 50%, reduce operating costs by 30%, and enhance market competitiveness.