Casting Services

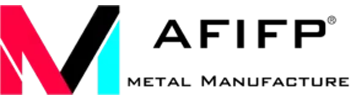

AFI Industrial Co., Ltd.provide professional casting services, from precision mold design to efficient die-casting molding. We control every detail to ensure the precise size and smooth surface of parts, and provide cost-effective solutions for your projects to help you reduce overall costs.

Quick response to orders and shortened production cycle.

Tolerance down to 0.01mm

The fastest delivery time is 3-15 days

Years in Business

5-Star Reviews

Active Customers

Counties Served

Our Casting Capabilities

AFI Industrial Co., Ltd. have a mature casting service system and can provide you with professional casting customization solutions. Whether it is a simple structural part or a complex precision part, we can accurately control the molding accuracy, surface finish and structural strength of aluminum alloy, zinc alloy and other materials to ensure that there are no sand holes or pores, and the dimensional tolerance is strictly controlled within ≤0.05mm/m to meet the diverse needs of customers.

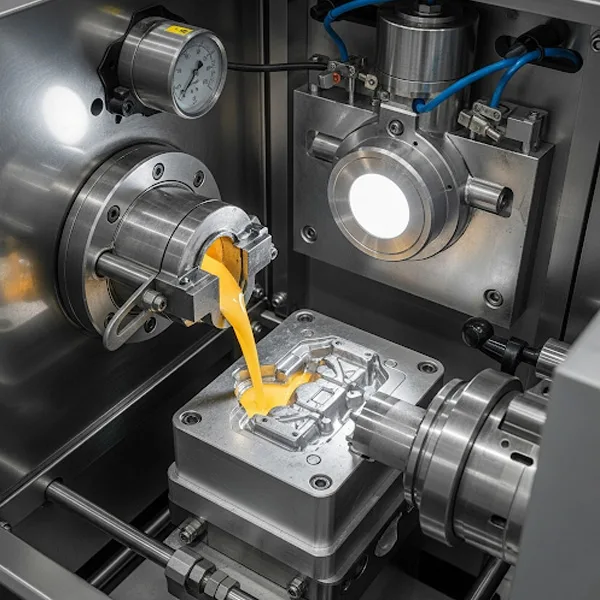

Custom CNC Machining Materials

We have a complete metal material library with more than 100 kinds of high-quality metal materials. We help customers quickly develop prototypes and manufacture high-precision complex parts. These materials can meet diverse needs and provide solid material guarantees for customers’ production and manufacturing work at different stages and with different requirements.

Why Choose Our CNC Processing Services?

One-to-one communication service

You only need to upload any type of drawings and you will receive a quote within 2 hours. Our professional engineers will analyze your design to prevent misunderstandings and communicate with you to provide you with a reasonable quote.

Precision production parts

We take materials, processing, surface treatment and coordinate measuring machine (CMM) testing seriously to ensure the consistent quality of parts from prototype design to mass production. Before delivery, we will conduct a detailed inspection of the quality of the parts to eliminate defective products.

Fast delivery cycle

We have introduced advanced five-axis CNC machining centers and equipped with professional quotation personnel to ensure a fast delivery cycle of 3-15 days. At the same time, we will reasonably set the order priority according to the specific needs of customers and the complexity of the order.

Real-time messaging

To protect your rights, we will provide each customer with exclusive technical support throughout the entire process from quotation to delivery, so you can contact us at any time. We will respond and answer any questions you raise quickly until you receive the parts you are satisfied with.

Casting Technical Standards

| Dimension | Standards |

| Minimum part weight | 1g |

| Maximum part weight | 10kg |

| Minimum part size | 20×10×5 mm |

| Maximum part size | 750×600×300 mm |

| Minimum wall thickness | 1.5 mm |

| Maximum wall thickness | 40mm |

| Minimum possible batch | 500pcs |

Metal Casting FAQs

The metals commonly used in die casting include zinc, copper, aluminum, magnesium alloys, etc.

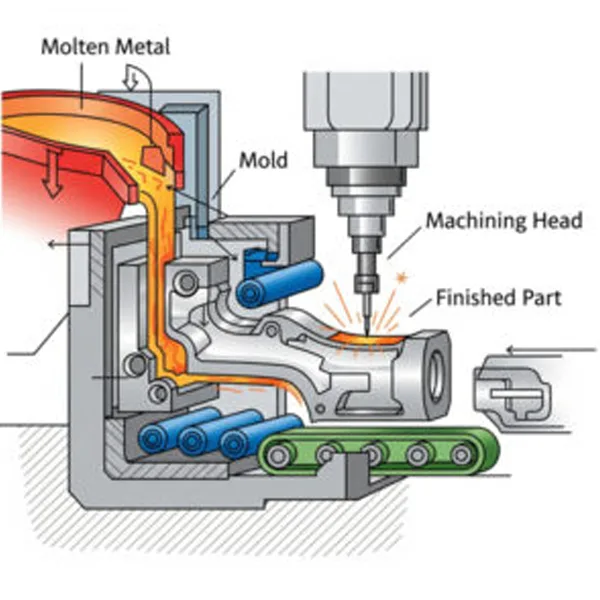

Our company’s casting processes include lost-wax casting, die casting, sand casting, powder metallurgy and forging. Our engineers can select the most suitable casting method for your product based on its characteristics.

For small batches (<100 pieces), we prefer sand casting or lost-wax casting. This process has low mold costs and the overall unit cost is the lowest. For large batches (>10,000 pieces), we prefer high-pressure die casting (HPDC). The high mold costs are spread out by high-speed automation, resulting in the lowest unit cost.

Our engineers will select the most suitable molding process for you based on the quantity and performance of your product.

For metal small parts, our company usually takes 15 to 25 days for normal mold production. With an urgent order, it can be completed within 7 to 10 days (this requires factory downtime plus night shifts). For medium and large-sized cast steel/iron parts (resin sand, lost foam casting), the normal processing time is 20 to 30 days, and the expedited processing time is 14 to 18 days.

Let us work together to create brilliance

AFI Industrial Co., Ltd.provides professional machining solutions, including product design, engineering drafting, CNC programming, precision manufacturing, laser cutting, surface treatment, assembly, and packaging. Our production process system can help customers shorten production cycles by 50%, reduce operating costs by 30%, and enhance market competitiveness.